Grundfos DMX Dosing Pumps

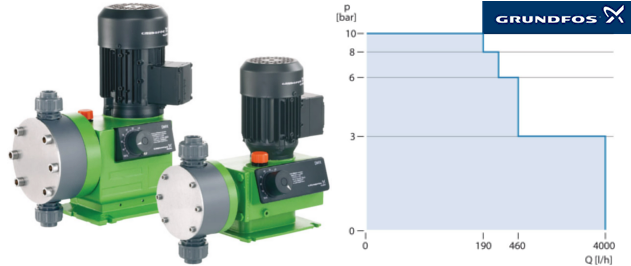

Grundfos DMX are trusted and recognized for their reliability and effectiveness in dosing applications worldwide. These pumps are equipped with a sturdy diaphragm-based design, ensuring consistent and precise dosing of chemicals. With minimal flow variation and linearity deviation, the DMX pumps offer accurate control over chemical dosage, making them an ideal choice for a wide range of industries.

One of the key features of the Grundfos DMX range is its advanced technology that provides superior performance and precise control over chemical dosage. The diaphragm dosing pumps design ensures consistent and accurate dosing, allowing for optimal performance in various applications.

The compact design of the Grundfos DMXis not only cost-effective but also space-saving. These pumps are specially engineered to provide efficient and reliable performance while taking up minimal space. The reduced footprint they require is particularly beneficial in installations where space is limited or at a premium.

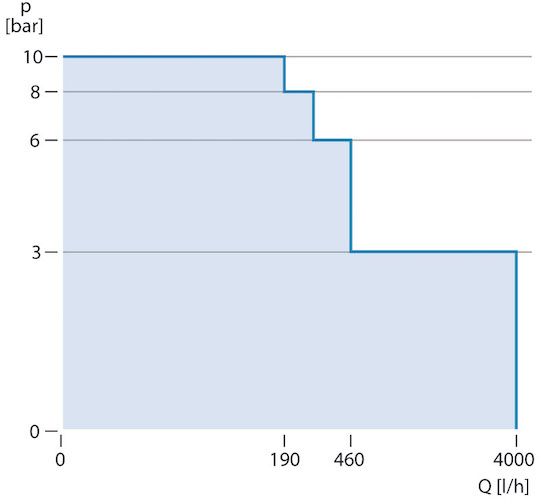

In terms of technical specifications, the DMX pumps have a maximum flow rate of up to 4000 l/h, with double-head versions capable of up to 2 x 4000 l/h. The equipment can withstand pressures of up to 10 bar and operate at liquid temperatures up to 50°C. The diaphragm design guarantees dosing flow variation below ± 1.5%. The linearity deviation is kept below 4 % at all times.

The DMX range offers versatility with various motor options suitable for different frequencies (50 Hz, 60 Hz, 100 Hz) and can include EX classified or ATEX-certified motors if needed. Additionally, these pumps are available in 12 different dosing head sizes, providing flexibility to meet specific requirements.

Overall, the Grundfos DMX range stands out for its reliability, efficiency, precise dosing capabilities, compact design, and versatility in variousapplications. These pumps are the preferred choice for many industries due to their minimal maintenance requirements and high-quality performance.

Reliable and Effective Applications

- Minimal maintenance required

- Versatile with a wide flow range

- Variety of dosing head sizes, materials, and accessories available

- Precise dosing of chemicals with low flow variation and linearity deviation

- Accurate dosing is always ensured.

Applications

The Grundfos DMX range is suitable for a variety of industries and applications.

The applications of Grundfos DMX are extensive, including drinking water treatment, wastewater treatment, pulp and paper industry, textile industry, cleaning water treatment, food and beverage industry (including dairies), cooling tower water treatment, and low-pressure boiler feed water treatment.

Some examples include:

1. Water Treatment: The Grundfos DMX are ideal for water treatment applications such as disinfection, pH adjustment, and chemicals.

2. Chemical Industry: The precise dosing capabilities of the DMX pumps make them suitable for various chemical processes, including mixing and blending.

3. Agriculture: Farmers can use DMX pumps for fertilization and irrigation purposes, ensuring accurate dosing of nutrients and chemicals to plants

Features and Specifications

The Grundfos DMX pumps are equipped with a range of features and specifications that make them a reliable choice for dosing applications. The diaphragm-based design ensures consistent and precise dosing of chemicals, with minimal flow variation and linearity deviation. This allows for accurate control of chemical dosage, ensuring optimal performance in various industries.

-

Next Generation Technology

Grundfos DMX are at the forefront of next-generation technology, providing advanced solutions for dosing applications across various industries. These pumps are designed with efficiency and reliability in mind, offering superior performance and precise control over chemical dosage.

One key feature of the Grundfos DMX range is its diaphragm-based design. This innovative design ensures consistent and accurate dosing of chemicals

- The compact design is cost-effective and space-saving.

The Grundfos DMX are renowned for their compact design, which not only makes them cost-effective but also space-saving. These Grundfos DMX are specially engineered to provide efficient and reliable performance while taking up minimal space in various applications.

One of the primary advantages of the compact design of DMXis the reduced footprint they require. This is particularly beneficial in installations where space is limited or at a premium.

Benefits

- ✔︎ Accurate dosing – all the time

- ✔︎ Smooth and low-pulsation dosing

- ✔︎ Compact design – saves money an space

Technical Data

- ✔︎ Flow Rate: Up to 4000 l/h (double-head versions up to 2 x 4000 l/h)

- ✔︎ Max Pressure: 10 bar

- ✔︎ Liquid temperature: 50°C

Variants

- ✔︎ The versatile DMX range offers high-quality motors for 50 Hz, 60 Hz, 100 Hz, as well as EX classified or ATEX-certified motors, if required.

- ✔︎ DMX pumps are available in 12 different dosing head sizes.

- ✔︎ Double-head versions are available.

Applications

- ✔︎ Drinking water treatment

- ✔︎ Waste water treatment

- ✔︎ Pulp and paper industry

- ✔︎ Textile industry

- ✔︎ Cleaning water treatment

- ✔︎ Food and beverage industry, dairies

- ✔︎ Cooling tower water treatment

- ✔︎ Low-pressure boiler feed water treatment