ArgalAIR

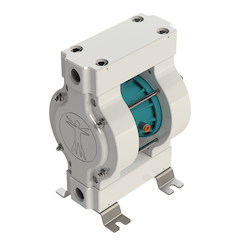

Revolutionary diaphragm pump

Replacement of valves and membranes while in line

Adjustable flow

Air saving

½", 1" and 1"½

Solid UHMW-PE

Connections: ½" to 2"

ATEX (Zone 2)

For abrasive & corrosive fluids

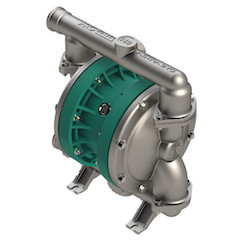

Up to 715 L/min

Stainless steel 316 Electropolis 125 Ra

Superior quality Teflon membrane, gas impermeable

Improved air consumption

Quieter integrated exhaust less sensitive to frost

Versions from ½" up to 2"

Various versions

Aluminum

Electro-polished stainless steel

PVDF

Polypropylene (PP)

Versions from ½ up to 2"

Connections: 2 ", 3" & 4 "

AISI 316L, Duplex, Bronze or UHMW-PE

ATEX zone 2

Up to 1280 L/hour

Connections: 3 "& 4"

FPR fiberglass construction

High chemical resistance

and mechanical

Up to 1280 L/hour

ArgalAir AODD Pumps

Revolutionizing Diaphragm Reliability and Lifespan

A Unique Air Pulsation System for Increased Durability

Unlike other AODD pumps on the market, ArgalAir pumps stand out with an innovative air pulsation system through six conduits, rather than a single air inlet, as is the case with competitors. This unique feature is a considerable advantage as it ensures a more evenly distributed pressure across the diaphragms.

Significant Reduction in Diaphragm Fatigue

By preventing concentrated pressure on a single point, ArgalAir pumps minimize the polymer fatigue of the diaphragms. This wider distribution of pressure drastically reduces the risk of diaphragm rupture, which is often the Achilles’ heel of AODD pumps.

Discover the experience of one of our major clients.

Unmatched Reliability in the Industry

This major innovation results in significantly longer diaphragm life, greatly reducing the need for maintenance and production downtime. For industries where operational continuity is crucial, ArgalAir pumps offer a more durable and secure pumping solution.

A Distinct Competitive Advantage

In a market dominated by established brands like ARO ®, Wilden ®, VersaMatic ®, Yamada ®, Sandpiper ®, and Graco ®, ArgalAir positions itself as an innovator offering superior technology. This exclusive feature makes ArgalAir a strategic choice for companies seeking reliable and efficient pumping solutions.

Optimal Safety and Performance

Furthermore, this unique technology ensures not only increased longevity of components but also contributes to better performance and safer usage.

This is particularly relevant in environments subject to strict standards such as ATEX.

In Summary

ArgalAir AODD pumps distinctly stand out from the competition thanks to their revolutionary design. This innovation brings significant added value to industries, ensuring increased durability, reliability, and safety, while reducing the frequency of maintenance interventions. ArgalAir thus affirms itself as a preferred choice for professionals seeking cutting-edge pumping solutions.

SPS Pumps — A Vital Link in the Chain of Excellence

At the heart of the remarkable performance and innovation offered by ArgalAir pumps is the pivotal role played by SPS Pumps. Known for their expertise, dynamism, and top-tier supplier relationships, SPS Pumps stands as a crucial connector between Argal Pumps’ advanced technology and the demanding industrial market. This synergy between SPS Pumps and Argal Pumps is not just about providing high-quality pumping solutions; it’s about creating a collaborative environment where expertise and innovation thrive. SPS Pumps’ deep understanding of industry needs and their ability to adapt quickly to market demands complement Argal Pumps’ commitment to technological advancement and reliability. Together, these two entities forge a partnership that delivers more than just pumping solutions – they offer a guarantee of performance, efficiency, and continuous support, ensuring that every client not only receives an exceptional product but also benefits from a comprehensive, expert-backed service experience.

Why Choose For a Diaphragm Pump

Diaphragm pumps offer many advantages over other types of industrial pumps.

See rather!

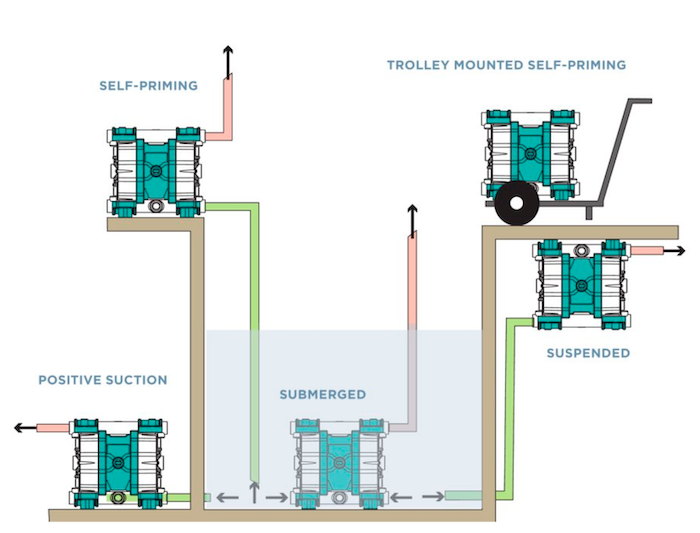

Self-Priming

The pump design allows high suction lift even at dry start and with heavier fluids.

Submersible

If external materialare compatible,then the pump can run submerged in the liquid by simply running the exhaust line above the liquid level.

Variable flow rate and discharge pressure

ARGALAIR offers the ability too vary flow and discharge pressure up to 120psi with a simple adjustment of the air supply.

Shear Sensitive

The gentle pneumatic movement makes the ARGALAIR an excellent choice for shear sensitive fluids.

Dead-head

Because the discharge pressure can never exceed air inlet pressure, the discharge line can be closed with no damage or wear. The pump will simply slow down and stop.

Handles a wide variety of fluids withhigh solids content

No close fitting or rotating parts so liquids with high solids content can be easily pumped, actually any liquids with max of90% solids.

Portable and simple installation

ARGALAIR pump can be easily transported to the application site. Simply connect your air supply line and liquid lines and the pumpis ready to perform. There is no complex control for installing and operating.

Safe

ARGALAIR pumpis operated by compressed air and are intrinsically safe.

Able to run dry

Membrane pumps are relatively insensitive to dry running, which will not be a problem, for example during filling.

Diagram of Typical Installations of a Diaphragm Pumps