Drum Pumps for Every Application

A drum pump is primarily used to transfer fluids from drums or IBC containers. Whether mobile or stationary, these transfer pumps are adaptable to nearly all types of fluids, whether viscous or low-viscosity, neutral, corrosive, or aggressive, flammable or hard to ignite, with or without solids.

Jessberger drum pumps typically come equipped with a powerful universal motor (JP-180 640 W or JP-280 with 825 W). They can be used to transport all low to moderately viscous liquids from drums and containers. In the case of centrifugal drum pumps, the viscosity limit is about 1000 mPas and up to a density of 1.9.

For more viscous fluids, the use of an eccentric screw drum pump or a pneumatically controlled diaphragm pump is recommended.

Here, the viscosity limit reaches up to 100,000 mPas.

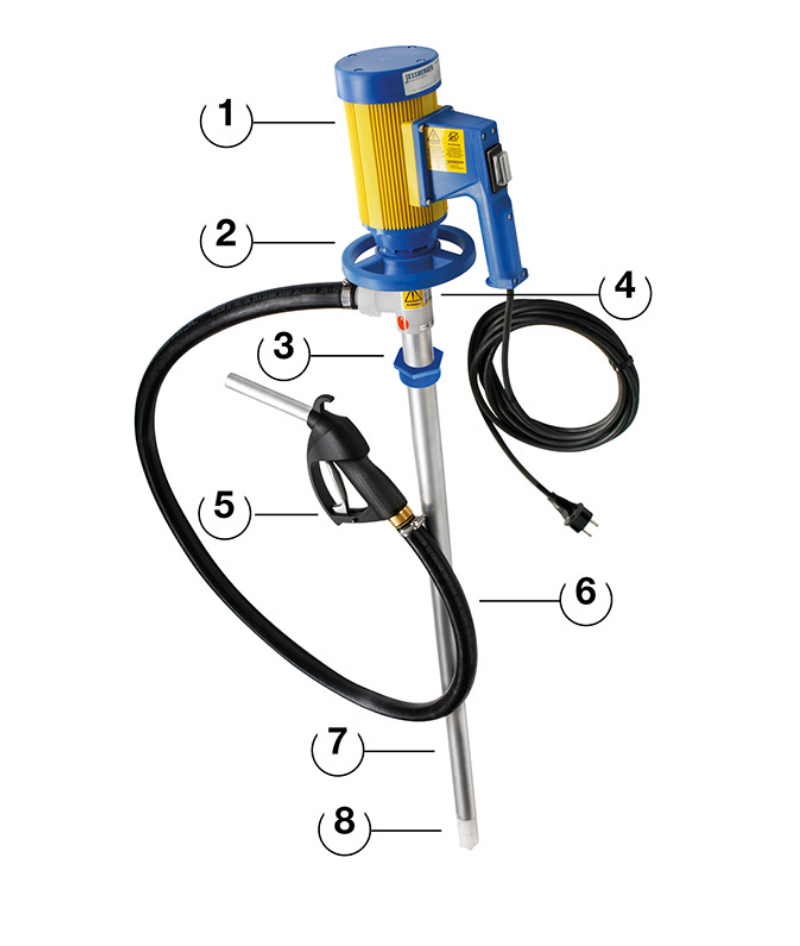

Structure of a Drum Pump

1. Motor – electric or pneumatic

2. Handwheel – for connecting the drive

3. Adapter – for fixing to the drum

4. Hose connection

5. Nozzle (fuel)

6. Discharge hose – available in various models

7. Pump tube – material varies based on the liquid

8. Pump foot

The Tubes

Depending on the fluid and application, Jessberger offers four different materials for the tube.

- ✔︎ Polypropylene

- ✔︎ PVDF

- ✔︎ Aluminum

- ✔︎ Stainless steel 316Ti

- ✔︎ Tube length from 200 mm to 1800 mm, available up to 3000 mm upon request.

The exact specifications of the fluid, application temperature, and environment are critical factors in selecting the appropriate material.

The plastics polypropylene and PVDF are used in the drum pump range for neutral, aggressive, and non-flammable fluids, particularly for acids, alkalis, and cleaning agents.

A polypropylene drum pump can be used for almost all standard chemicals in the chemical or electroplating industry, up to a temperature of 50°C.

Jessberger PP drum pumps are used for fluids such as sodium hydroxide, hydrochloric acid, slightly concentrated sulfuric acid, iron(II) chloride, iron(III) chloride, etc.

Tubes for Special Liquids

For highly aggressive fluids such as sulfuric acid over 90%, chromic acid, hydrofluoric or nitric acid, the drum pump tube must be made of PVDF (polyvinylidene fluoride), with a Hastelloy shaft.

This chemically resistant material can also be used up to a fluid temperature of 90°C.

In the oil and automotive industries, aluminum drum pumps are primarily used for pumping diesel, gear oil, heating oil, hydraulic oil, machine oil, mineral oils, and engine oil, etc. With a drum pump like the JP-280 Alu 1 000 Set, you can pump all non-flammable, low and medium viscosity mineral oil products, up to a maximum viscosity of 1,000 mPas from cans, 200-liter drums, or 1000-liter IBC containers.

For pumping highly flammable liquids, in explosive environments (Ex), as well as in the food and pharmaceutical industries, Jessberger includes a range of high-quality, conductive stainless steel 316Ti tubes in their production program.

The Motors

The electric motors of Jessberger drum pumps are also equipped with an overload circuit breaker with an integrated low-voltage trigger, which prevents the pump from restarting after a voltage drop.

Optionally, the electric motors can be controlled by an external command via a control cabinet. You can also adjust the pumping capacity of the drum pumps with an optional speed controller.

In the case of pneumatic motors, the air supply pressure is varied.

Motors for ATEX Applications

For ATEX applications all the pneumatic motors JP-AIR 1, 2 & 3 are particularly suitable.

Where an electric motor is required, Jessberger drum pumps can be equipped with the JP-440 SS Ex Protection motor.

Its main specifications are:

- ✔︎ 230 Volt, 50/60 Hz, 550 Watt, Class II 2G Ex db IIC T6 Gb, IP55 protection

- ✔︎ Double insulation, protection II

- ✔︎ Overload protection switch with integrated low-voltage trigger

- ✔︎ 5 m cable without plug

- ✔︎ Certification number EPS 17 ATEX 1 088 X, compliance: IECEx EPS 17.0045X

Drum Pumps for Laboratory Use

Jessberger also offers laboratory versions of its pumps with tube lengths of 500 mm or 700 mm. These laboratory versions are specially designed for laboratory applications, where precise fluid transfer is necessary.

Thanks to the versatility of the tube diameters, they can adapt to different types of liquids and their viscosities.

Whether it’s transferring small volumes or handling delicate substances, the laboratory versions of Jessberger drum pumps, with their various tube lengths, provide the flexibility and reliability needed in laboratory settings.

Key Benefits of Jessberger Drum Pumps

- ✔︎ Quick disconnection of the drive from the tube with a few rotations allows the combination of one motor with different tubes for different fluids.

- ✔︎ A wide range of accessories such as drum and threaded adapters, fluid-resistant hoses, nozzles and guns, wall mounts, or flow meters are available upon request.

- ✔︎ Easy disassembly and quick cleaning of the pump tubes.

- ✔︎ Universal electric motors in 230, 115, 24 volts in various performance and protection classes.

- ✔︎ Pneumatically operated motors (for a maximum operating pressure of 6 bars).

- ✔︎ Tubes in polypropylene, PVDF, aluminum, or stainless steel 1.4571.

- ✔︎ Universal JESSBERGER motors can be combined with all tubes, they are lightweight, manageable, and powerful for almost all low or slightly viscous fluids.

Discover the Superior Performance of Jessberger Drum Pumps with SPS Pumps

At SPS Pumps, we are proud to be a specialized supplier of industrial pumps, offering a wide range of high-quality Jessberger drum pumps.

Why choose Jessberger drum pumps?

1. Expertise in Industrial Pumps: As a centre of excellence with cutting-edge technical expertise, SPS Pumps is your trusted partner for all your industrial pump needs.

2. Target Audience: Our drum pumps are aimed at production managers, maintenance services, and their teams working across various industrial sectors.

3. Versatile Applications: Our drum pumps are designed to excel in fluid processing, water management, solvents and adhesives, acids and bases, etc.

In short, for all fluids encountered in the industry, particularly in the food, chemical, and pharmaceutical industries, as well as in transportation, agriculture, biomethanation…

SPS Pumps — Centre of Excellence, expertise, and advice, the ideal partner for industry.

Call us now at +32 2 657 23 53.

Benefits

- ✔︎ Quick Disconnect Feature: The rapid disconnection mechanism enables easy switching between motors and pump tubes for handling different fluids, enhancing versatility for industrial applications.

- ✔︎ Advanced Design: Jessberger drum pumps feature a sophisticated yet user-friendly design, ensuring efficient and safe operation in demanding industrial environments.

- ✔︎ Extensive Range of Accessories: From drum and thread adapters to fluid-resistant hoses, nozzles, wall mounts, and flow meters, we offer a wide array of accessories to customize your pumping solution.

- ✔︎ Easy Maintenance: Designed for quick disassembly, these pumps allow for hassle-free cleaning and maintenance, ensuring long-term reliability.

- ✔︎ Universal Electric Motors: Available in 230, 115, 24 volts, our motors come in various performance and protection classes, catering to diverse industrial requirements.

- ✔︎ Pneumatic Control Motors: Ideal for operations requiring up to 6 bars of working pressure, offering precision control in fluid management.

- ✔︎ Diverse Material Options: Choose from polypropylene, PVDF, aluminum, or stainless steel 1.4571 pump tubes, each tailored for specific industrial fluids and applications.

- ✔︎ Lightweight Universal Motors: Jessberger’s universal motors are lightweight, easy to handle, and powerful, suitable for almost all thin and slightly viscous fluids, enhancing operational efficiency.

- ✔︎ Adaptable for Intermittent Operation: Our drum pump motors, both stationary and non-stationary, are ideally suited for intermittent operation, providing flexibility in industrial processes.

- ✔︎ Flow Rate: 600 L to 18 m3/h

- ✔︎ Max Head: 12 bar

- ✔︎ Liquid Temperature: up to 200°C

- ✔︎ Flanges: 1/2″ to 1 1/2″

- ✔︎ Power: from 250 W to 2.2 kW

- ✔︎ Tube Length: from 200 mm to 3000 mm

- ✔︎ Tube Diameter: 28 mm to 130 mm

- ✔︎ Pump Type: Impeller, Turbine, or Eccentric Screw

- ✔︎ Pump Body Materials: PP, PVDF, Stainless Steel 316, Aluminium

- ✔︎ Shaft Materials: Stainless Steel, Hastelloy

- ✔︎ Drum emptying, IBC container draining

- ✔︎ Chemical, food products, oils, etc.

- ✔︎ Acids, concentrated bases

- ✔︎ Oils, hydrocarbons, emulsions

- ✔︎ Viscous fluids up to 100,000 cP

- ✔︎ And much more…

- ✔︎ ATEX

- ✔︎ FDA

- ✔︎ Drum Adapter

- ✔︎ Hoses

- ✔︎ Flow Meter

- ✔︎ Foot Valve

- ✔︎ Nozzle