ArgalAIR QUANTUM DDQ

The Most Advanced Diaphragm Pump

- ✔︎ Replacement of membranes and balls without dismantling the pump from its circuit

- ✔︎ Reduced air consumption

- ✔︎ Extremely robust construction, body in UPPE or PTFE

- ✔︎ Can be installed directly on the production line

- ✔︎ Can run-dry

- ✔︎ Adjustable flow and pressure

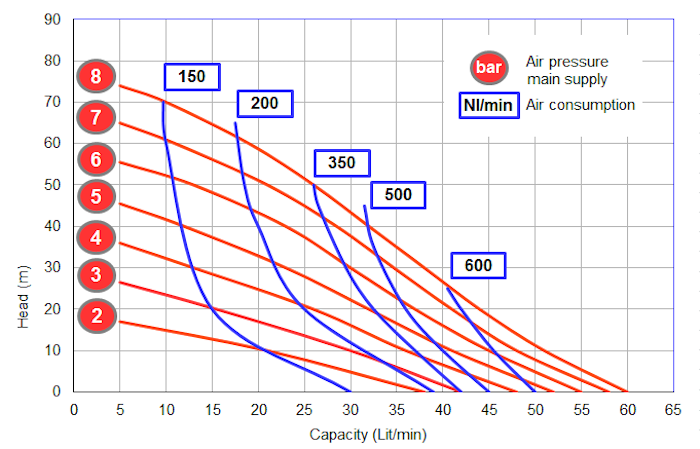

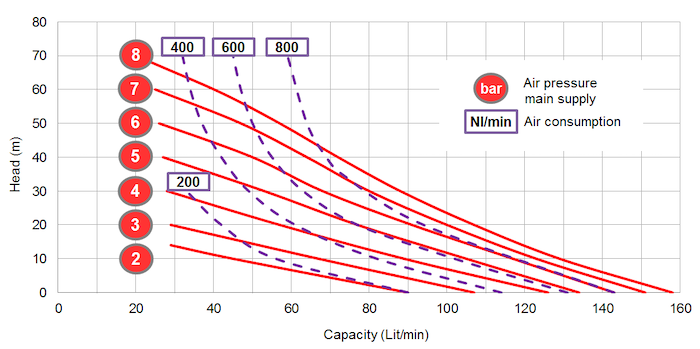

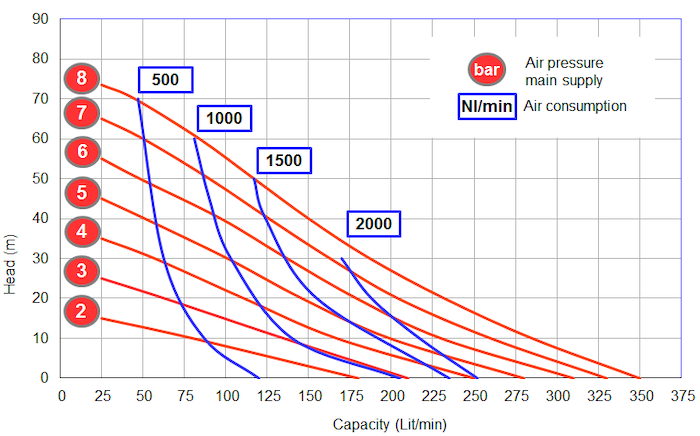

- ✔︎ Up to 450 L/min

- ✔︎ Head up to 70 m

Argal Quantum AODD Pumps — Breakthrough in Reliability & Technology

The Argal QUANTUM AODD pumps are original double diaphragm pumps that simply offer optimised

performance and far more interesting benefits than traditional double diaphragm pumps.

Thanks to the construction from solid in pure thermoplastic polymers,

Argal QUANTUM AODD pumps are mechanically and chemically highly resistant allowing

the pumping of aggressive liquids such as nitric acid or sodium hydroxide,

a reduction in air consumption and an extended life cycle.

Furthermore, the execution is more solid and precise thanks to the functional innovation,

the structural and constructive compactness of the various components.

QUANTUMs are the perfect solution for applications related

to chemical processes and processes with heavy liquids.

They are currently available in sizes ½”, 1″ and 1½”.

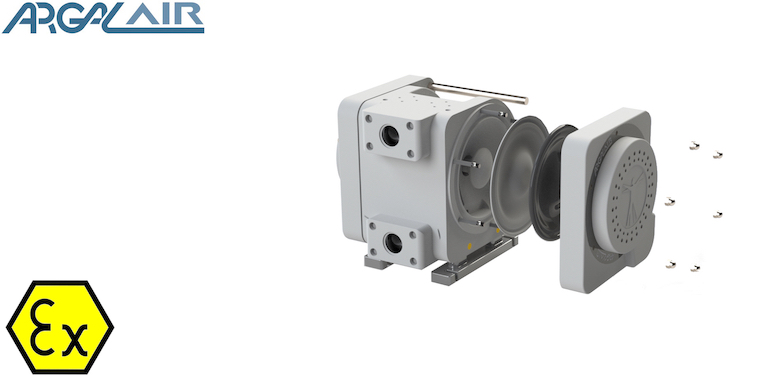

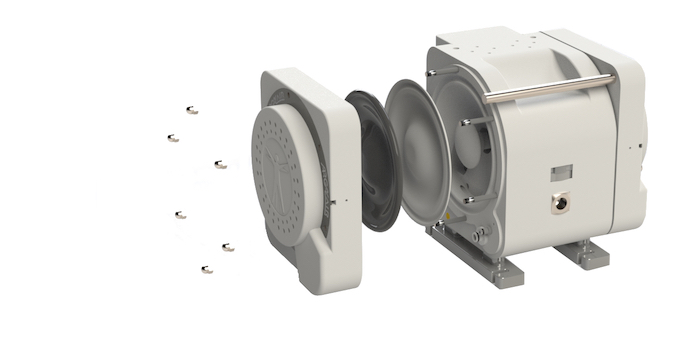

✔︎ The Double Membrane — A New Approach

The construction of the QUANTUM pumps is different from the standard double diaphragm pumps.

The membranes are not connected. This allows their quick and much simplified replacement, in-line,

and in total safety even with a positive pressure of the liquid in suction up to 7 bar.

Furthermore, the membranes are not perforated at all as all competitive AODD pumps.

This leads to a far more resistant membrane as well as a much easier replacement.

Even if a membrane would break, the pumps fluid will not return to the air supply system.

✔︎ The Valves — An All New Concept

Easily disassemble the check valves for cleaning, maintenance or replacement

without removing the pump from the system or from its connections.

✔︎ The Quick Drains — Zero Risk of Frost

Double diaphragm pumps are known to suffer from ice formation in the distributor.

Our engineers offer you an innovative solution:

a gasket has been added to divert the exhausted air, at very low temperature, towards the exhaust chamber.

This unique feature allows the AODD Quantums to be completely insensitive to the humidity present in the air,

maintaining high efficiency without losing performance.

ATEX regulation

All standard executions, both plastic and metal, are suitable for operating in an explosive environment

classified as Zone 2 (Series II 3/3 IIB T4) . For Zone 1 applications (Series II 2/2 GD IIB T4),

the pump is manufactured with bodies and other conductive parts for all plastic and metal versions.

| Sectors | Applications |

|---|---|

| Chemicals & Pharmaceuticals | Acids, alkalis, alcohol, solvents, emulsions, ultra pure liquids |

| Semi-Conductors | Heat transfer and ultra pure liquids, elelctrolyte solutions, mecure, solvents |

| Surface Treatments | Galvanic baths, acids, solvents, sludge, varnishes, enamels |

| Water Treatments | Neutralisation, flocculation |

| Paper & Printing | Glues additives, vanishes, inks, latex, acids, resins, pigments, sludges, adhesives, sokium silicate, titanium oxide |

| Photovolaic | Ultra pure liquids, sludge, abrasive solvents |