Argal Frontiera Centrifugal Pumps – TMF — TGF — ZMF — ZGF

- ✔︎ ISO 2858 Centrifugal Pumps

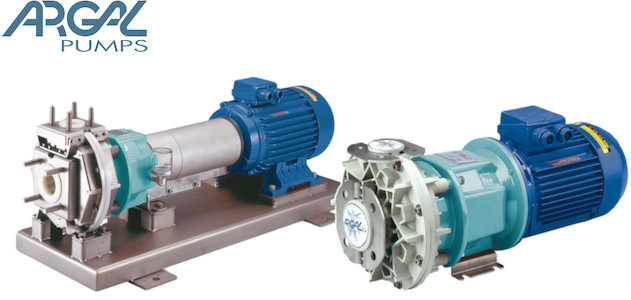

- ✔︎ Mag-Driven or Mechanical Sealed

- ✔︎ Made of Thermo-Polymers Chosen for Each Application

- ✔︎ Various Options to Fit All Applications

- ✔︎ Standard or ATEX Versions

- ✔︎ Up to 90 m3/hour

ISO 2858 Centrifugal Pumps for Corrosive Fluids, Clean and with Solids

The FRONTIERA pumps are compliant with ISO 2858 conformity, and are available in different constructions and materials to offer our clients the best solution.

Made in thermoplastics and pure fluoro-polymers, the FRONTIERA offers various solutions to best solve the pumping of chemical liquids in their numerous applications.

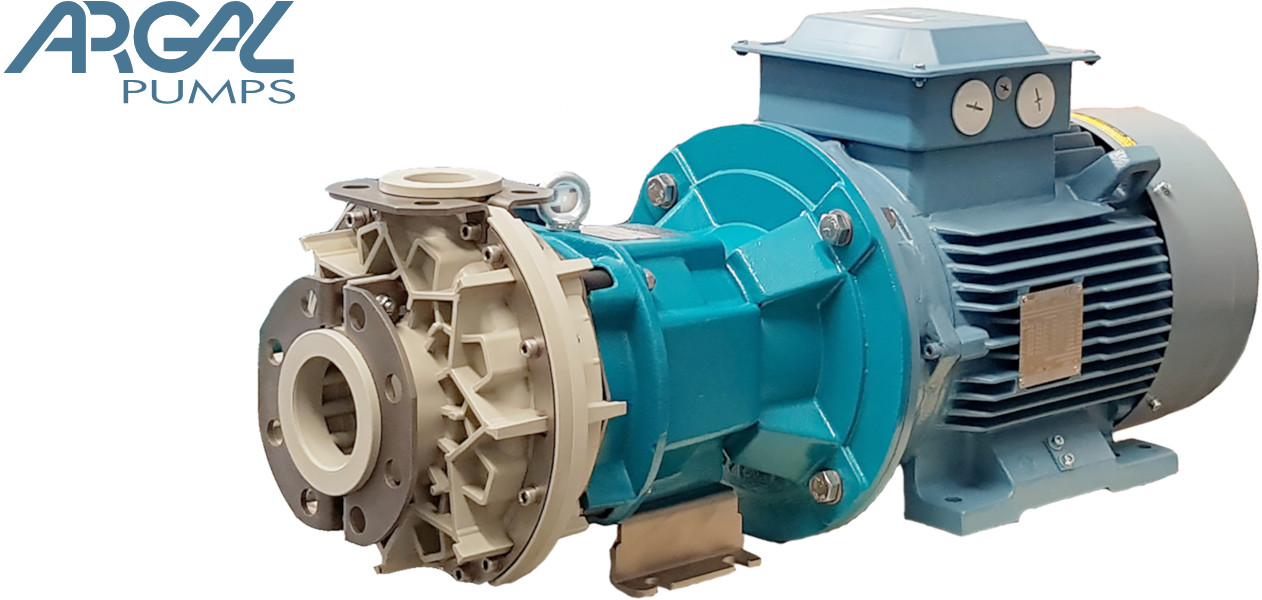

The innovation is in the external parts in stainless steel instead of cast iron. They can be magnetic drive or mechanical seal .

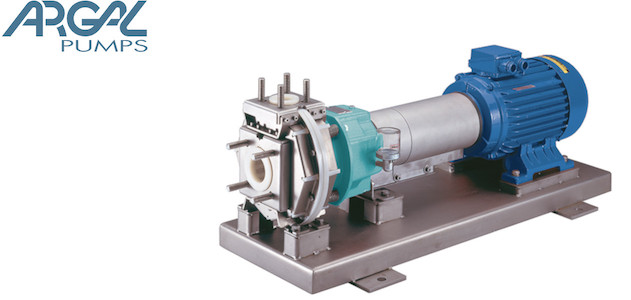

The coupling of the pump to the motor can be achieved by means of a mechanical support and a removable or flanged self-centering flexible joint .

There are 2 magnetic versions (TGF and TMF) and 2 mechanical versions (ZGF – ZMF).

Mechanical Transmission — Z

In the sealed version, the impeller is mounted on the motor shaft and the liquid leakage on the motor is prevented by sliding flushings (mechanical seals) with the appropriate material.

To compare with the magnetic driven version, the mechanical seal allows the pumping of uncleaned liquids, liquids ladened with solids and even viscous liquids.

Magnetic Driven Transmission — T

The motor shaft connects the external magnet with the internal one which is linked to the impeller.

This allows the moving of the liquid and it also prevents from liquid leakage.

This construction is chosen for pumping cleaned liquids (R2), slightly abrasive (P2) and moderately abrasive liquids (X2).

The magnetic driven version si not ideal for pumping liquids ladened with solids.

Innovative External Structure

N Integral series

The external structure of N Series is realised of stainless steel and replaces teh traditional plastic flanges.

The special design of the fastening fittings minimises the mechanical load pressure on the volute casing.

R Armoured Series

In the R series, the stainless steel sheeting replaces teh cast iron armour that is often damaged quickly.

The new armour supports both the loads on the inlet / outlet fittings and protects the volute casing from internal liquid hammers or accidental external blows.

Stainless Steel Armour

The stainless steel armour embeds the pump casing while the rear casing, made of PP or E-CTFE, is strengthened with an additional chamber made of polyamide.

Easy Maintenance

FRONTIERA Mag-Driven Wet-End complete casing can be easily detached from other parts, without opening it.

This is a remarkable technical alternative for spare parts.

Long Coupled FRONTIERA Mechanical Sealed series are equipped with the back Pull-Out system that allows to take the internal and mechanical pars off without dismantling the body and motor form the baseplate.

ATEX Compliance

The FRONTIERA centrifugal pumps made of pure PP or E-CTFE in the armoured version can operate in the ATEX zones.

They are used in the surface application (Group II) and are part of the category 3, level of protection 2.

FRONTIERA pumps can operate in gaseous atmospheres (Zone 1 and Zone 2).