Argal SATURNevo Fiberglass Centrifugal Pumps

- ✔︎ Entirely made of Fiberglass

- ✔︎ Closed or Long Coupled to fit all configuration

- ✔︎ High Strength & Durable

- ✔︎ 5 pump body versions to best fit the fluid characteristics

- ✔︎ Powered by motors from 3 up to 160 kW

- ✔︎ Up to 1350 m3/hour

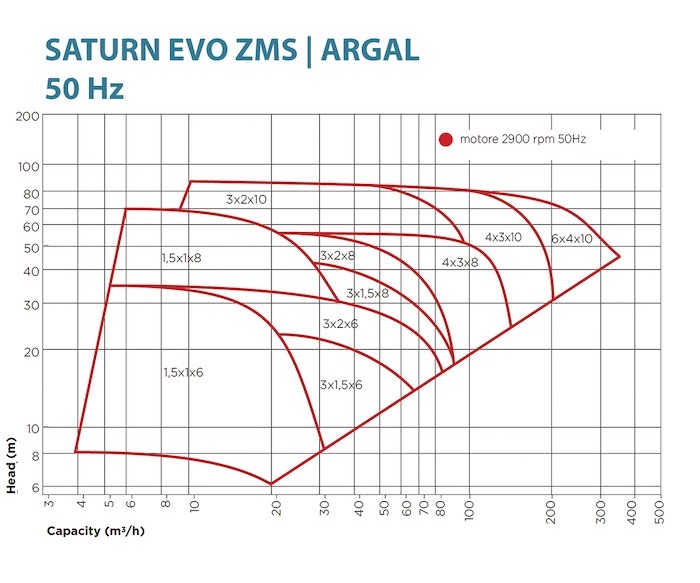

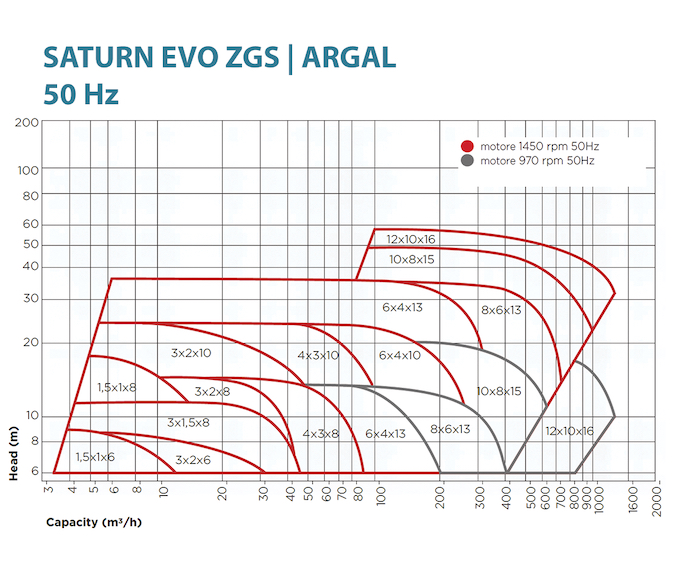

SATURN EVO — ZGS & ZMS

The evolved SATURN EVO range consist of horizontal centrifugal single-stage pumps.

They are entirely manufactured internally, using a molding process with the RTM technique.

This technique allows the production of the pieces by injection in a closed mold

in which the reinforcement structure consisting of fiberglass in a continuous matrix has previously been housed.

There are 2 models of Saturn FRP fiberglass pumps:

the ZGS, version with elastic coupling and the ZMS, monobloc version.

5 Versions of Construction

- V1G — for corrosives liquids including acids, alkalis, detergents, brine and sea water.

- V1A — for liquids with a low concentration of abrasion, ie fossil shell flour, ashes or titanium dioxide.

- V1C — for corrosive liquids such as sodium hypochlorite (NaOCl) or hydrogen peroxide (H2O2).

- V1F — for fluoride acid (HF) and other liquids with fluorine

- V1X — for operation in ATEX areas.

Long-Coupled ZGS

The coupling of the pump to the motor with a flexible joint delivers an extended operational life

to the mechanical parts of the pump and therefore is the preferred solution for heavy duty application and continuous applications.

ZGS pumps with elastic coupling are equipped with the back pull-out system that allows the dismantling

of the internal and mechanic parts of the pump without disconnecting the casing from the fittings and without moving the motor.

Closed-Coupled ZMS

The closed-coupled series offers installations for power requirements for up to 37 kW with significant mechanical advantages.

The shaft of the pump is supported by a bearing located in the lantern;

this bearing counters the radial load of the shaft and by reducing its overhung section,

it reduces the loads on the bearings of the electric motor contributing to extent the pump lifecycle.

This solution is characterised by the reduction of the overall dimensions and allows installing these pumps in plants and compact systems.

| Sectors | Applications |

|---|---|

| Aquariums / Zoos | Saltwater |

| Chemical Process | Aids, Chemical waste, Waste Water |

| Desalination | Filtration, Seawater Intake, Chemical Transfer, Concentrated Brine |

| Electric Utilities | Coal Pile Run-Off |

| Electronics | Acids, Chemical Waste |

| Metal Finishing | Chromic Acids, Pickling Acids, Plating Solutions |

| Petrochemicals | Acids, Chemical Waste |

| Pharmaceuticals | Organic Solvents |

| Pulp & Paper | Bleach |

| Mining | Abrasives and Corrosives |

| Scrubbers/Odors Control | Acids & Caustics |