Argal PRIMA TMP

Centrifugal Pumps in Synthetic Material

- ✔︎ No sealing components — Mag-Drive

- ✔︎ No metallic part in contact with the fluid

- ✔︎ Threaded of flanged connections

- ✔︎ ATEX

Argal PRIMA TMP — Adapted Construction to Chemicals

The pumps of the TMP serie are mag-driven centrifugal, horizontal axis, close-coupled types,

the pump casings are entirely built with reinforced thermoplastic polymers,

and materials for internal components are ceramic oxides, HD carbon, fluorinated elastomers which mean any contact of metallic parts with the pumped fluid is avoided.

This combination of materials is correctly chosen to obtain the best in the performances and on a small scale: chemical pumps.

Versatile

You can practically pump all the chemicals at low and medium temperatures with all the bodies in GFR-PP (glass Fibre reinforced polypropylene) or CFF-E-CTFE (Ethylene-ChloroTriFuoroEthylene carbon fibre filled). Strong magnetic coupling made up of rare-earth materials (Neodimium Iron Boron) and “N” (Standard), P (powered) or S (strong powered) versions allow to pump, also at maximum flow, liquids with 1.05, 1.35, 1.8 specific gravity respectively.

Hermetic System

The outlet magnet assembly driven by the motor shaft, produces a magnetic torque dragging up in rotation the inside magnetic assembly on which the impeller is over moulded.

The rear casing, having appropriate shape and joined to the volute casing, divides the two magnetic units, making an hermetic case all around the impeller.

Safety

The drive magnetic system finally excludes any type of rotating seal.

Special solutions and employed materials occasionally allow dry running operation,

avoiding any damages inside the TMP pumps. These solutions require an internal structure type “R“.

ATEX

Argal PRIMA pumps made of PP or E-CTFE + Carbon Fibre are perfect for operating into Explosive Atmospheres (ATEX).

They can run in Group II areas and category 1, 2 or 3 according to the level of protection

Thanks to the carbon fibre, they are ideal for gaseous atmospheres (zone 1 and zone 2).

- Traitements de l’Eau

- Aquarium

- Machines d’Art Graphique

- Équipement de Teinture

- Équipement de Gravure

- Équipement Médical

- Processus de Développement Photographique

- Laboratoires chimiques

- Fabricants de Batteries de Stockage

- Galvanoplastie

- Récupération d’Argent

- Détartrage

- Fongicides et Pesticides

- Systèmes Solaires

- Systèmes Laser

- Réfrigérateur pour bateaux

- Réfrigérateur

- Machines à glace

- Distributeurs automatiques de boissons

- Solutions chimiques corrosives

- Liquides toxiques

- Eau de mer

- Eau Pure (eau déminéralisée)

- Des Produits Chimiques pour Conserver les Aliments

- Blanchisserie

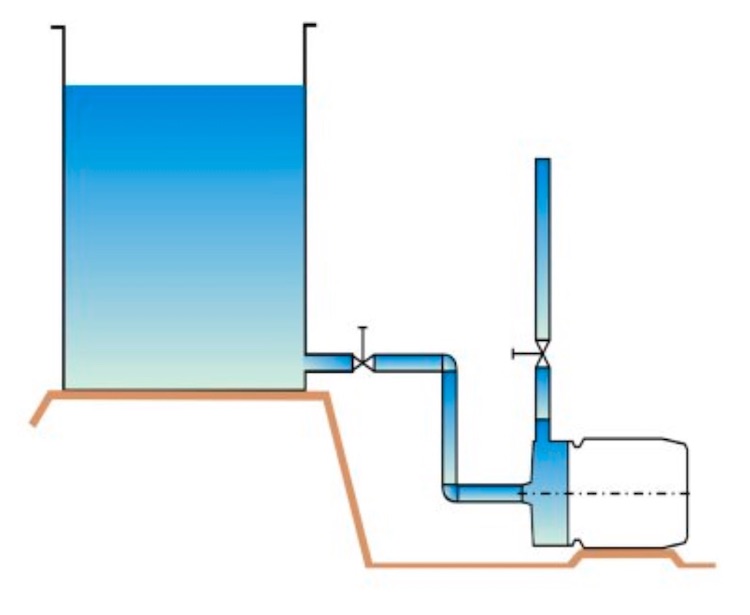

The Argal PRIMA TMP pumps can be installed to operate as recirculation, filtration, mixing, heating, cooling

or cleaning pumps for clean liquids from a process to another.

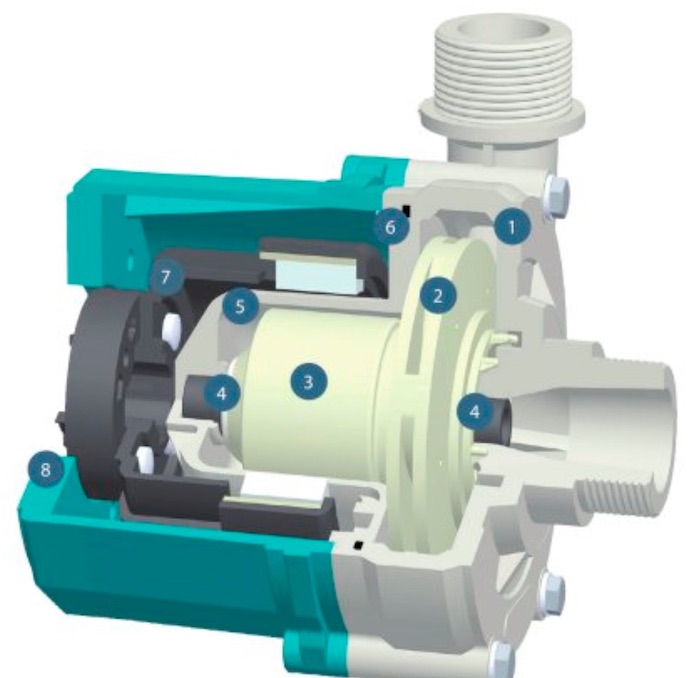

- 1 Volute Casing

- 2 Centrifugal Impeller (covered type)

- 3 Centrifugal Impeller Magnetic Transmission

- 4 Guide Bushing

- 5 Rear Casing

- 6 OR gasket

- 7 Drive Magnet Assembly

- 8 Bracket