- ✔︎ Ideal for thermal oils up to 320 °C and food oil applications

- ✔︎ Bearing without thermal oil, for greater safety

- ✔︎ High temperature transfer without need for cooling

- ✔︎ ISO 2858, Food Grade

- ✔︎ Compatible with Allweiler NTT® pumps

- ✔︎ Many parts in stock, very short reaction time

Single Stage Centrifugal Pumps Travaini TCD – Thermal Oil Pumps

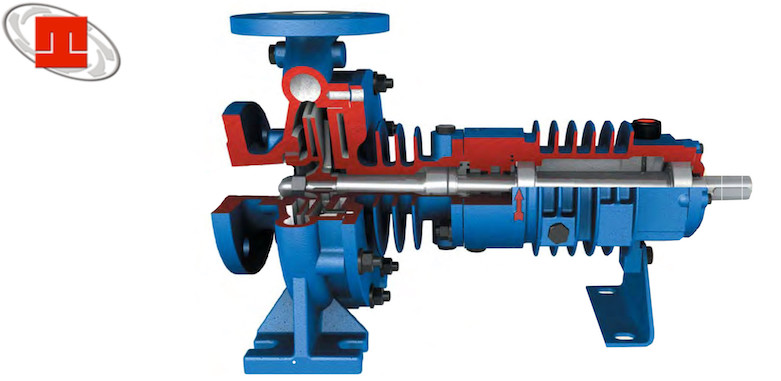

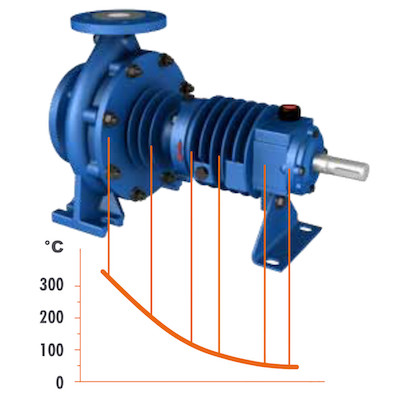

The Travaini TCD series pumps are specifically designed for transfer of thermal liquids up to 320 °C without the use of special cooling systems.

They meet the ISO 2858 / DIN 24256 standard.

Their great advantage is that the heat from the pumped liquid is blocked very effectively by a special barrier located between the pump body and the wheel. In addition, the special fins effectively dissipates heat from the pump housing and maintains an adequate operating temperature allowing the use of a standard mechanical seal.

The shaft is supported by two over-sized bearings, Series 3, with an oil bath of medium viscosity.

The materials used in the construction of TCD pumps are spheroidal cast iron or stainless steel ASI316.

Dimensions and features conform to ISO2858 / DIN 24256 standards.

Flow rate up to 350 m3/hour

Benefits over Allweiler NTT® Pumps

- ✔︎ Better heat dispersion thanks to its unique design

- ✔︎ Oversized bearings for better reliability

- ✔︎ No need to replace the wheel when changing washers

- ✔︎ Special design offers better reliability in pumping edible oils

Single-stage centrifugal pumps Travaini TCD/SP

The Travaini TCD/SP pump has been specifically designed for pumping edible vegetable oils.

Compared to the standard version, the TCD/SP model is fitted with an intermediate cover behind the mechanical seal, which acts as a spacer, attached to a tank containing oil compatible with the pumped one.

Bearing lubrication is therefore made with a specific oil and not with the heat transfer oil.

This is particularly important in food oil transfer applications. An intermediate chamber filled with a food fluid prevents the entry of air or contaminations with the lubricating oil in the process in case of breakage of the mechanical seal.

This precaution avoids that, in the event of damage to the mechanical seal, air can not enter the pump and oxidize the oil pumped, or that the oil of the bearings enters the pumping circuit, or vice versa.

Modèles Allweiler NTT® et leurs Equivalents en Travaini TCD

| Allweiler NTT | 25-160/11 | Travaini TCD | 25-160 |

| Allweiler NTT | 25-200/01 | Travaini TCD | 25-200 |

| Allweiler NTT | 32-160/01 | Travaini TCD | 32-160 |

| Allweiler NTT | 32-200/01 | Travaini TCD | 32-200 |

| Allweiler NTT | 40-160/01 | Travaini TCD | 40-160 |

| Allweiler NTT | 40-200/01 | Travaini TCD | 40-200 |

| Allweiler NTT | 40-250/01 | Travaini TCD | 40-250 |

| Allweiler NTT * | 50-160/01 | Travaini TCD | 50-160 |

| Allweiler NTT * | 50-200/01 | Travaini TCD | 50-200 |

| Allweiler NTT * | 50-250/01 | Travaini TCD | 50-250 |

| Allweiler NTT * | 65-160/01 | Travaini TCD | 65-160 |

| Allweiler NTT * | 65-200/02 | Travaini TCD | 65-200 |

| Allweiler NTT * | 65-250/01 | Travaini TCD | 65-250 |

| Allweiler NTT * | 65-315/01 | Travaini TCD | 65-315 |

| Allweiler NTT * | 80-160/01 | Travaini TCD | 80-160 |

| Allweiler NTT * | 80-200/02 | Travaini TCD | 80-200 |

| Allweiler NTT * | 80-250/01 | Travaini TCD | 80-250 |

| Allweiler NTT * | 80-315/01 | Travaini TCD | 80-315 |

| Allweiler NTT | 100-200/01 | Travaini TCD | 100-200 |

| Allweiler NTT | 100-250/01 | Travaini TCD | 100-250 |

| Allweiler NTT | 100-315/01 | Travaini TCD | 100-315 |

| Allweiler NTT | 125-250/01 | Travaini TCD | 125-250 |

| Allweiler NTT | 125-315/01 | Travaini TCD | 125-315 |

| Allweiler NTT | 150-250/02 | Travaini TCD | 150-250 |