- ✔︎ Effective and safe

- ✔︎ Extremely robust and reliable

- ✔︎ Built to last

- ✔︎ Low operating costs

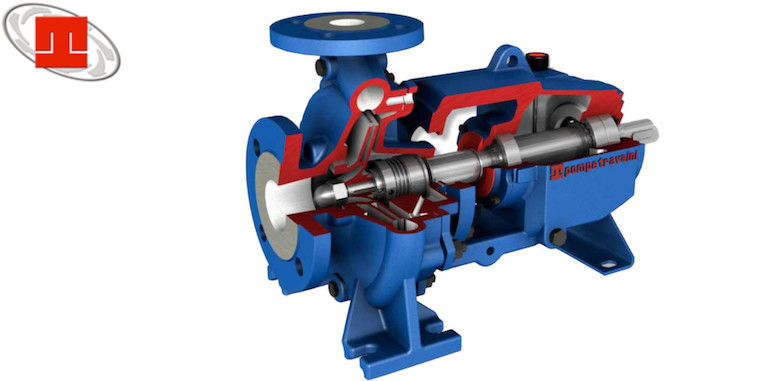

Single-stage Centrifugal Pumps Travaini TCH

Pumps of the Travaini TCH series and those derived from them meet the ISO 5199 class II standards.

These standards introduce new manufacturing criteria that are more stringent than the ISO 2858/DIN 24256 standards for dimensions.

These pumps are therefore suitable for more difficult conditions of use, particularly in the petrochemical industry, following the example of API standards.

These pumps are, furthermore, the result of constant research and long experience acquired with the old MCU-CH series in multiple jobs and application areas.

They also take into account the advice and advice of users.

The result is a perfectly developed product for:

- ✔︎ Robustness

- ✔︎ Efficiency

- ✔︎ Reliability

- ✔︎ Safety

- ✔︎ Long lasting

- ✔︎ Lower operating cost

Pumping of clean or slightly turbid, hot, overheated, acidic and basic liquids in the chemical, petrochemical, pharmaceutical, food, paper, wine, steel and textile industries, etc.

Flow rate up to <500 m3/h and pressure up to 16 bar.

External dimensions and performance according to ISO 2858/DIN 24256.

Wide choice of materials (from cast iron to Hastelloy).

High hydraulic efficiency and reduced NPSH values.

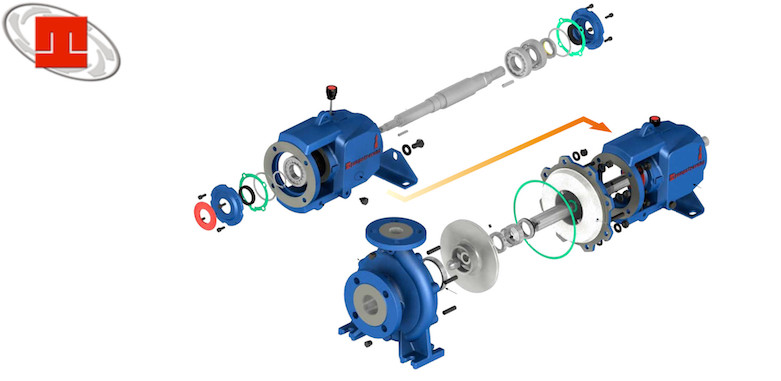

Single or double mechanical seal (ISO3069/UNI EN 12756) in each installation mode according to API rules.

Possibility of heating or cooling the pump housing and the mechanical seal housing.

The unit can receive type B5 engines up to 30 kW, thanks to a suitable coupling lantern, which not only guarantees a simple coupling but also a perfect alignment, even after transport.

TCT, TCA and TCD series pumps are derived from the TCH series.

They all have many common parts and are especially designed for specific pumping applications.

Technical specifications according to standards ISO 5199

- Corrosion allowance greater than 3 mm

- Oversized shaft to reduce bending (< 50 microns) and vibrations and increase the life of the mechanical seal

- Large distance between bearings for optimum value of L 3/D4

- Oversized bearings to support radial and axial loads with a service life greater than 25,000 hours

- Blocking the thrust bearing

- Threaded drain connection for any leaks

- Optional Visual oil level indicator

Technical specifications according to standards ISO 2858 / DIN 24256

- Wheels and pump bodies interchangeable with previous versions of MCU-CH series

- The seal between body cover and pump casing is anti-burst and asbestos-free

Technical specifications according to standards ISO 3069 – UNI EN 12756

- Shaft sleeve with the smallest dimensions to mount mechanical seals at the lowest cost and for the longest possible service life

- Internal circulation for better lubrication of the mechanical seal

- Lots of space available to accommodate all types of fittings

In addition, Travaini TCH pumps meet many other standards

- Compliance with ATEX Directive 94/9 / EC

- Performance test according to ISO 9906

- Vibrations according to ISO 10816-3 standards

- Balancing according to ISO 1940 standards