Grundfos BMS hs

Grundfos BMST

Grundfos BMSX

The Grundfos BMS range is a completely new range of booster modules

mainly used for reverse osmosis, filtration and ultrafiltration applications

that improve efficiency compared to earlier ranges.

It features a directly coupled pump powered by a permanent magnet motor

and Variable Frequency Drive (VFD).

The Grundfos BMS range comes in 3 different combinations:

- ✔︎ Grundfos BMS hs

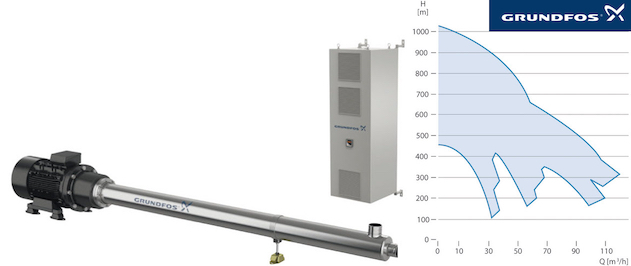

High pressure booster system. - ✔︎ Grundfos BMST

High pressure booster system with energy recovery via turbine.

Pressure booster module & energy recovery system with pressure exchanger.

Grundfos BMST booster systems consist of a Grundfos BMS hs pump and a Pelton turbine.

This provides the same capacity as a standard centrifugal pump,

and thus save up to 35% on the total energy consumption of the pump.

Grundfos BMST booster systems are suitable for desalination plants. - ✔︎ Grundfos BMSX

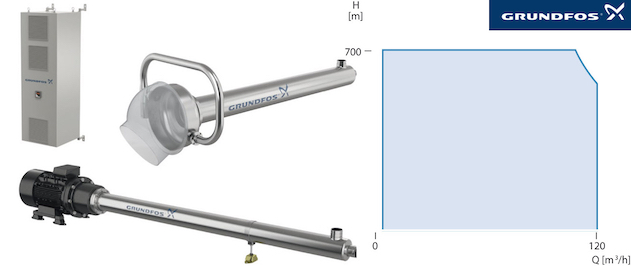

High pressure booster system with energy recovery via pressure exchanger.

The Grundfos BMSX booster system is designed for desalination of seawater and brackish water.

The BMSX system consists of a Grundfos BMS hs pump and a BMS hp pump

and an isolatable pressure exchanger with an efficiency of up to 98 %.

It can deliver 1500 m³ per day with an energy consumption of only 2 kWh per m³.

produced water.

The parts are made of Super Duplex stainless steel, polymer and ceramics,

which makes the module extremely resistant to the working environment.

It has a compact design and requires a very small installation area.

Benefits

- Energy savings due to high efficiency

- Easy maintenance and alignment due to improved design

- Easy integration in any water treatment system

- Extreme durability and reliability

- Very small footprint

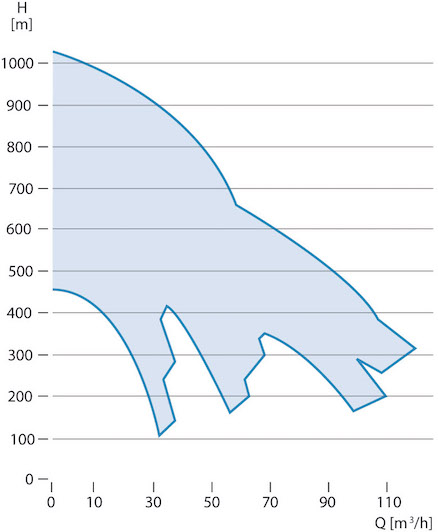

- Designed for high flows and pressure

- Speed ramp up and down are included

- VFD pre-set at duty point

Technical Data

- All critical components are super duplex stainless steel suitable for use in seawater and brackish water applications

- The shaft seal is made from carbon/silicon carbide, especially designed for high pressure

- The thrust bearing material is ceramic and carbon

- Pump bearings and seal rings are made of NBR rubber

- Built-in thrust bearing absorbing the axial thrust from the pump

Applications

- Reverse Osmosis systems

- Ultra filtration systems

- Filtration systems

- Pressure boosting systems

- Water supply