Grundfos SMART DIGITAL Dosing Pumps

Intelligent dosing pumps with new drive and adjustment mechanisms represent

the ideal solution for increasingly complex dosing.

They make life easier for users by keeping processes running precisely, reliably and cost-effectively.

SMART Digital dosing pumps meet these challenges by offering state-of-the-art drive technology,

a whole new dimension in user-friendly operation and an intelligent FlowControl system.

These properties ensure extremely precise, reliable and cost-effective processes

combined with the best possible price-performance ratio.

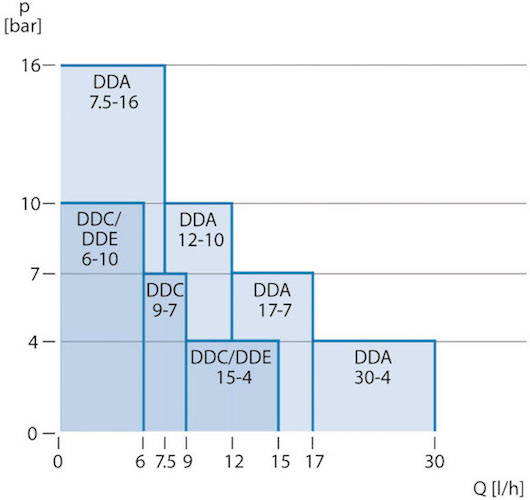

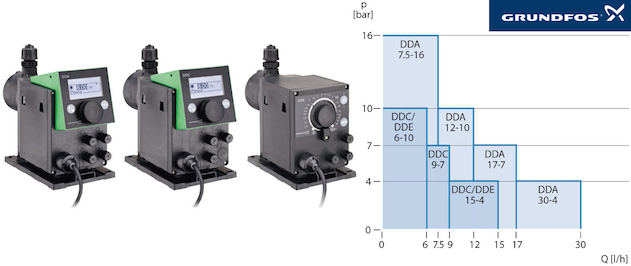

Three different pump ranges are offered, all featuring powerful, variable-speed stepper motors;

a universal power supply; and a full PTFE diaphragm that meets the most demanding requirements

for chemical resistance and durability.

Grundfos DDA

The DDA model is the pump for complex and demanding applications where

the focus is on maximum process reliability.

In addition to an extended capacity range and a turn-down ratio of up to 1:3000,

it boasts FlowControl, pressure monitoring, AutoFlowAdapt and integrated flow measurement.

The package for industrial applications is rounded off by additional operating modes

such as a week dosing timer and new functions such as auto deaeration.

Grundfos DDC

The DDC impresses with features such as simple, intuitive click-wheel operation

and a graphic LC display in more than 28 languages.

What’s more, all standard modes of operation and inputs/outputs such as analog control

or output relay can be integrated into control systems.

This pump is suitable for universal use thanks to highlights including the SlowMode (anti-cavitation) function

for highly viscous media and the straightforward calibration mode.

Grundfos DDE

The DDE is the cost-effective entry-level model with all the benefits of Digital Dosing

such as a maximum turn-down ratio of 1:1000 and smooth, continuous dosing.

This one model can replace a whole host of existing models with dosing rates ranging from 0.006 to 6 l/h.

The rate is set using a logarithmic scale that runs from 0.1-100 %.

The model’s straightforward pulse control, external stop function and empty level signal are ideal for basic OEM applications.

Simplicity

Easy Handling

Complete Overview

Remote Control

The pumps are extremely easy to use thanks to their thumbwheel.

The DDA and DDC models offer simple and intuitive navigation

via an LCD display with translated text in more than 28 languages,

which allows the user to set the flow rate directly on the display in ml/h, l/h or gph.

The large display shows the pump status by changing the colour of the backlight.

This allows quick and easy control.

Modularity

Flexible

Adapted to Any Environment or Situation

The high ratio considerably reduces the number of different models required.

All models have a universal plate for all common mounting methods.

The pump can be quickly and easily removed from the mounting plate.

The control cube can be easily rotated to a lateral or frontal position.

Maximum flexibility is provided by the many adjustment options,

supply voltages (100-240 V, 50/60 Hz) as well as a hydraulic connection kit.

The optional E-box and CIU housings allow the SMART Digital

in standard bus communication networks.

Flow Control Intelligence

Highest Process Reliability

The FlowControl function of the DDA prevents unwanted stoppages,

even with variable parameters such as operating pressure fluctuations.

The DDA provides an accurate diagnosis of faults typically encountered in applications such as

dosing with diaphragm dosing pumps. These faults are displayed in text form in the alarm menu.

The AutoFlowAdapt function ensures that dosing continues with the required flow rate,

even when it is subject to external influences.

In case of dosing of degassing liquids for example, the engine control

is automatically adjusted as soon as air bubbles are detected in order to drive them out

of the dosing head. The fluctuating back pressure no longer affects the required flow rate.

The speed control mechanism of the stepper motor automatically compensates for deviations.

The flow measurement function integrated in the DDA makes expensive additional equipment superfluous.

The instantaneous flow rate measured is shown directly on the display and can

also be integrated into the DDA to the control system via analog output or bus communication if required.

Process

- ✔︎ Disinfection

- ✔︎ PH control

- ✔︎ CIP

- ✔︎ Dosing of chemicals and biocides

- ✔︎ Precipitation and flocculation

- ✔︎ Filtration

- ✔︎ Reverse osmosis

Applications

- ✔︎ Treatment of drinking water

- ✔︎ Wastewater treatment

- ✔︎ Boiler water treatment

- ✔︎ Cooling water treatment

- ✔︎ Process water treatment

- ✔︎ Pool water treatment

- ✔︎ Chemical industry

- ✔︎ Ultrafiltration and Reverse Osmosis process

- ✔︎ Treatment of low pressure boiler feed water

- ✔︎ Food and Beverage Industry

- ✔︎ Paper Industry

- ✔︎ Textile industry

- ✔︎ Irrigation