- Clean air discharge

- Various service liquid handling as water, oil, solvents to serve all types of applications

- Pressure to less than 33 mbar

- Highly reliable and easy to maintain

- Large selection of materials

- Important stock and rapid reaction time

Liquid Handling Capability

Pumps are capable of handling even high volumes of vapours, condensables and liquids, without detrimental consequences to their performance or their mechanical reliability.

Pump service liquid can be water or other liquids such as oils, solvents etc. to satisfy almost any process requirements.

Discharge of Oil Free Air

With clean water as pump service liquid, the aspirated air (or gas) is “washed clean” within the pump. Contrary to other types of vacuum pumps the discharged air is therefore, completely free of any oils, carbon or plastic particles.

Pressure to Less than 33 mBar

Liquid ring vacuum pumps, type TRH in series with devices such as ejector and/or vacuum boosters can operate at pressure lower than 1 mbar.

Quality

Designed and manufactured under the ISO 9001 standards, every components is guaranteed for the selected materials, workmanship and performance through scrupulous inspections during production stages and final testing of finished product.

Compatibility with, among others, Flowserve SiHi Sterling® Vacuum Pumps and Hibon®

The Travaini Vacuum Pumps offer many options that are 100% compatible with the leading brands on the market, mainly Flowserve SiHi Sterling®, but also Hibon® which was betting on Brand portfolio of Ingersoll Rand®.

We suggest you to contact our technical service for more information on compatibilities and availability.

Fewer Components

Through engineered design innovations and co-operation with the finest technologically advanced foundries, the pumps are manufactured with less components than typically required. Fewer parts add to the rigidity and toughness of the pumps, they are easier to assemble and maintenance is greatly facilitated.

Compact

The conventional stuffing boxes construction is eliminated with the Travaini standard design. The shaft length is greatly reduced, eliminating the potential danger for shaft deflections and vibrations to the mechanical seals which would increase seals and bearing wear.

Standard Mechanical Seal

In keeping pace with today technology. Pompetravaini has standardized all pumps to accept unified mechanical seats to DIN 24960 standards. Also available upon request, are constructions with double mechanical seals (tandem or back to back) or cartridge type mechanical seals.

Large Selection of Materials

In addition to the standard materials. Pompetravaini pumps are also available with special exotic materials such as Ni-Resist D2B, Hastelloy B or C. Uranus B6, etc. to meet specific requirements.

Mounting to B3 or B5 Motors

Pompetravaini standard design may be base-mounted coupled to motors type B3. Pumps up to 30 kW can also be close coupled to motors type B5 utilizing specially designed attachment flange. This close-coupled arrangement allows utilization of standard readily available electric motors, eliminates lengthy alignment procedures and costly breakdowns associated with misalignments. Overall dimensions are reduced and engineered baseplates are no longer required.

Mechanical Reliability

With the simple design of liquid ring pumps there are no reciprocating parts, no valves or sliding vanes.

The impeller is the only rotating component with no metal-to-metal contact. Pump operation is therefore with minimal wear, vibrations free and noise levels are greatly reduced.

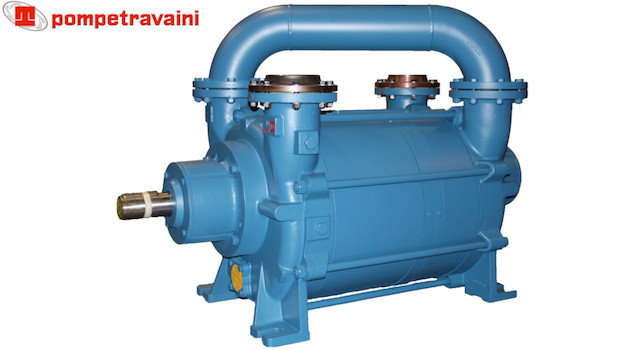

Characteristics of the Double Stage Vacuum Pumps Travaini TRH

- Double Stage Vacuum Pumps

- Capacity 3 up to 3500 m3/h

- Minimum Pressure ranging from 33 mBar to 200 mBar

Characteristics of the Single Stage Vacuum Pumps Travaini TRS

- Single Stage Vacuum Pumps

- Capacity 10 up to 3,500 m3/h

- Minimum Pressure ranging from 200 mBar to 900 mBar

Compatibility between Flowserve SiHi Sterling ® and Travaini Vacuum Pumps

100% Compatible Interchangeable Vacuum Pump Table

| SiHi Sterling | LPH 40411 | Travaini | TRSC 40-150 | |

| SiHi Sterling | LPH 40106 | Travaini | TRSC 40-80 | |

| SiHi Sterling | LOH 20107 | Travaini | TRSC 32-50 | 24 mm L+R |

| SiHi Sterling | LOH 20103 | Travaini | TRSC 32-20 | 24 mm L+R |

| SiHi Sterling | LPH 45316 | Travaini | TRHC 40-190 | 38 mm L+R |

| SiHi Sterling | LPH 45311 | Travaini | TRHC 40-140 | 38 mm L+R |

| SiHi Sterling | LPH 45008 | Travaini | TRHC 40-110 | 38 mm L+R |

| SiHi Sterling | LOH 25309 | Travaini | TRHC 32-60 | 24 mm L+R |

| SiHi Sterling | LOH 25007 | Travaini | TRHC 32-45 | 24 mm L+R |

| SiHi Sterling | LOH 25003 | Travaini | TRHC 32-20 | 24 mm L+R |

Table of Vacuum Pumps Comparable in Performance, but not fully Compatible

| SiHi Sterling | LPH 70540 | Travaini | TRSE 125-1550 | |

| SiHi Sterling | LPH 70530 | Travaini | TRSE 125-1250 | |

| SiHi Sterling | LPH 70123 | Travaini | TRSB 100-980 | |

| SiHi Sterling | LPH 60527 | Travaini | TRVX 1005 | 70 mm L+R |

| SiHi Sterling | LPH 60523 | Travaini | TRVX 1003 | 70 mm L+R |

| SiHi Sterling | LPH 50523 | Travaini | TRVA 65-450 | |

| SiHi Sterling | LPH 40516 | Travaini | TRSC 50-220 | |

| SiHi Sterling | LPH 75340 | Travaini | TRHE 100-1600 | |

| SiHi Sterling | LPH 75530 | Travaini | TRHE 125-1250 | |

| SiHi Sterling | LPH 75320 | Travaini | TRHE 100-870 | |

| SiHi Sterling | between LPH 65327 & LPH 75320 |

Travaini | TRHE 80-750 | |

| SiHi Sterling | LPH 65327 | Travaini | TRHC 80-600 | |

| SiHi Sterling | LPH 55320 | Travaini | TRHB 50-420 | |

| SiHi Sterling | LPH 55316 | Travaini | TRHB 50-340 | |

| SiHi Sterling | LPH 55312 | Travaini | TRHB 50-280 |

Compatibility with Hibon® Vacuum Pump Models

Hibon® vacuum pumps, which were once part of the Ingersoll Rand® group, are in some cases 100% compatible with Travaini models.

We suggest you to contact our technical service to determine exactly the compatibilities and possibilities of interchangeability.

Current Hibon® Models

- ✔︎ Hibon AL 01+

- ✔︎ Hibon AL 02+

- ✔︎ Hibon AL 03+

- ✔︎ Hibon AL 04+

- ✔︎ Hibon AL 05+

- ✔︎ Hibon AL 07+

- ✔︎ Hibon AL 10+

- ✔︎ Hibon AL 14+

- ✔︎ Hibon AL 20+

- ✔︎ Hibon AL 30+

- ✔︎ Hibon AL 40+

- ✔︎ Hibon AL 50+

- ✔︎ Hibon AL 70+

- ✔︎ Hibon AL 140+

- ✔︎ Hibon ALPHA 05+

- ✔︎ Hibon ALPHA 07+

- ✔︎ Hibon ALPHA 10+

- ✔︎ Hibon ALPHA 14+

- ✔︎ Hibon ALPHA 20+

- ✔︎ Hibon ALPHA 25+

- ✔︎ Hibon ALPHA 30+

- ✔︎ Hibon ALPHA 40+

- ✔︎ Hibon ALPHA 50+

- ✔︎ 1 Stage Hibon DELTA A

- ✔︎ Hibon DELTA B

- ✔︎ 2 Stages Hibon DELTA C