Wangen Pumps

Ideal for hygienic applications

Very gentle fluid transfer

Excellent in foodstuff

The Most Reliable

And the Lowest Cost of Ownership

Wangen Pumps provides standard progressive cavity pumps as well as special solutions

for the handling of difficult, viscous and abrasive media for virtually all industrial sectors

in almost all technical ranges of applications.

- ✔︎ Exceptionally robust construction

- ✔︎ Easy to maintain

- ✔︎ Equipped with cardan drive giving them exceptional reliability

- ✔︎ Modular design, offering many options for the most complex applications

- ✔︎ Lowest operating costs thanks to their reliability and the very reasonable price for spare parts

- ✔︎ Complete range of progressive cavity pumps

- ✔︎ Complete range of Twin Screw pumps

- ✔︎ For industrial, food, pharmaceutical applications

- ✔︎ …

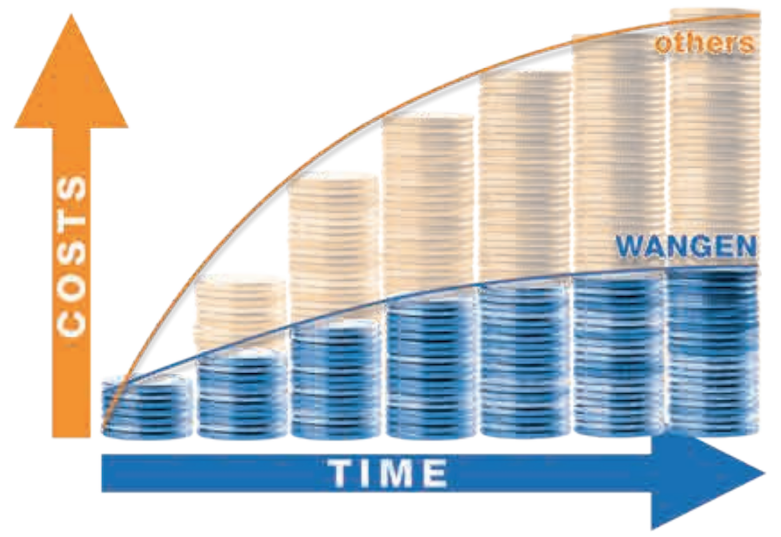

The Lowest Operating Costs

When purchasing a pump, we always recommend that you consider

the operating costs and weigh them against the initial investment.

Maintenance costs, production downtime and energy account

for most of the total costs over the life cycle of a pump.

Our philosophy offers a decisive advantage here:

keep the lowest total life cycle costs possible.

Our approach is to keep the frequency of maintenance to a minimum

by judiciously choosing the model and its nominal speed,

a mistake often made to limit initial investments.

We achieve this goal by the robustness of the Wangen pumps,

but also by the correct choice of the needed model, and most importantly,

limit the frequency of maintenance and repairs to a minimum.

We also offer a spare part price strategy that is very competitive.

Each failure that is avoided on a production line saves not only

the cost of spare parts, but also maintenance costs and production downtime.

Save by guarantying your peace of mind.

Wangen Pumps Cardan Joint

Wangen pumps are all equipped with cardan joint transmission.

Compared to all competitors who use conventional transmissions with kneecaps and pins,

the benefit is simply considerable.

The bearings are practically indestructible,

whereas the traditional transmission joint is a wear part well known of the services of maintenance.

In addition, the cardan transfers a much higher power with much less loss.

All of these features lead to much less risk of breakage.

Easy and Fast Maintenance

In order to guarantee the highest availability of equipment,

most of our customers prefer to maintain their pumps within their services.

Among their many strengths, the ease of inspection of the state of the components

is certainly a very big advantage.

The pumps are studied in order to reduce the intervention time to a minimum.

Whether it’s replacing a stator, a rotor, a mechanical seal,

the design of the pump makes it so much easier to maintain.

Know-How is the Key to Reliability

Especially in the field of special applications and under heavy-duty conditions

Pumpenfabrik Wangen has proven to be a competent partner for plant builders

and customers from the industry.

Wangen Pumpen and SPS collaborate to offer the most adequate Progressive Cavity Pump solution

to meet customer’s needs technically as well as in terms of Total Cost of Ownership

by taking into account all parameters including maintenance and spare parts costs.

You have a project with progressive cavity pumps. Call us, we will be happy

to meet with you to help build your project.

A Few Applications

- Food Processing

- Breweries

- Chemicals

- Bio-methanation

- Water treatment

- Slaughterhouses

- Cement industry

- Sugar industry