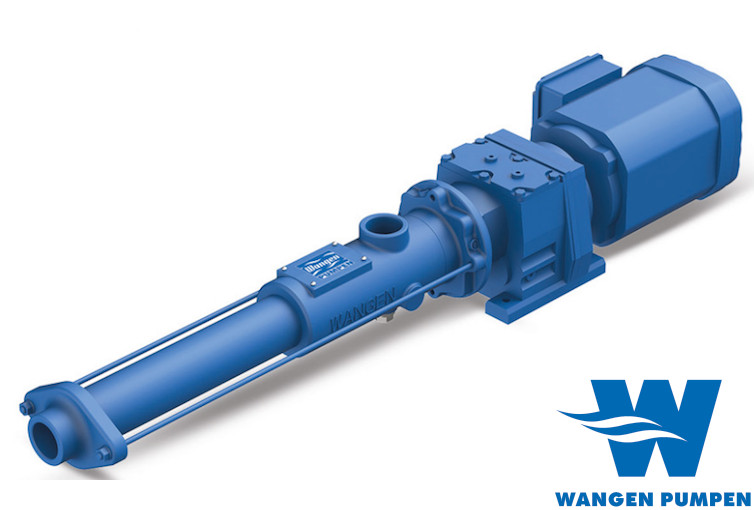

The Wangen KB-S GG

Simple Maintenance & Very Compact Progressive Cavity Pumps

Ideal for applications requiring flow rates up to 5 m³/h, Wangen Series KB-S GG pumps

can be found in many applications such as metering, polymer transfer,

and many other industrial fluids.

They can reach a maximum pressure of 16 bar.

The central advantage of the pump concept lies in the small number

of parts within each individual modules.

The pump has, in contrast to those of the KL-series,

a block housing and is on the Drive built.

It reliably conveys media of various viscosities.

The progressive cavity pump WANGEN KB-S GG is one of the

standard product groups of the pump factory.

- Good dosing properties

- Compact design

- Rigorous modular principle for high flexibility

- Constant flow speed in the suction housing prevents deposits or sedimentation

Main Benefits

- Low Life Cycle Costs

- Excellent price/performance ratio

- High pressure performance

- Maintenance-friendly

- Good price/performance ratio (standard product group)

- Optionally with base plate or mobile

- Good dosing properties

- Constant flow speed in the suction housing prevents desposits or sedimentation

- Rigorous modular principle for high flexibility

- Compact design

- High suction lift (self-priming)

But also

- large variety of flange connections

- Stator with S-cone inlet for optimum filling of the pumping chamber

- various rotor/stator geometries (S, L and H geometry)

- Mature, robust universal joints with extended service life; non-clogging; with or without prefeeding screw

- Various mechanical seals as standard versions

- Sturdy block housing for various gear flange fittings

- flexible drive selection

Suitable for the following media

- Waste oil

- Bilge water

- Dispersion glue

- Fat

- Flocculants

- Sewage sludge

- Industrial wastewater

- Mineral oil

- Paperpulp

- Plaster

- Refinery sludge

- Saline solution

- Cutting oil

- Starchglue

- Hydrogen peroxide

- Polymere

- Coating binder

Technical Features

| Flow Rate | Up to 5 m³/h |

| Maximum Pressure | 16 Bar |