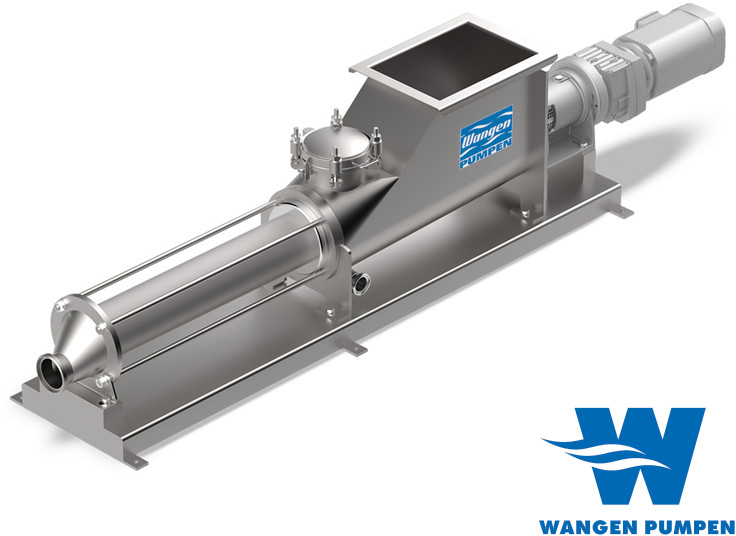

Wangen KL-RF Pumps

Wangen KL-RF Hygienic PC pumps are designed for loading and

transferring materials such as butter, ice cream, margarine, etc.

They are very robust and meet the requirements of the CIP (Clean in Place).

The WANGEN KL-R progressive cavity pump and its specially designed hopper housing

with its modular sealing system, enable the gentle conveyance of medias

without influencing the structure or quality of it.

The KL-RF model, which is particularly easy to maintain and has few dead zones,

is perfect for use in the food industry.

Wangen KL-RF pumps are particularly suitable for introducing very thick materials

into a fluid, such as, for example, the introduction of butter or margarine.

They have many technological advantages, such as inspection access, mechanical seals

which are independent of the direction of rotation and do not require any maintenance.

In addition, the Wangen KL-RF pump is available in different geometries to suit every situation.

Also available, conical entry stators to facilitate the introduction into the body of drier materials.

Very simple to clean it is 100% CIP and a really robust construction

to guarantee a continuous operation.

- 100% CIP certified.

- Easy maintenance.

- Construction materials FDA certified upon request.

- Various rotor/stator geometries to match all needs.

- Robust construction.

Main Advantages

- Easy maintenance

- Rational and highly functional design

- Gentle product transfer

- Optional heating or cooling jackets

- Compact design

- Long service life

- Low life cycle costs

- Easy, space-saving assembly

- Quick and easy manual cleaning

- Excellent price/performance ratio

Suitable for the following media

The Wangen KL-RF pump is ideal for loading and transferring very thick fluid.

- Butter

- Margarine

- Butter and margarine in blocks

- Crème glacée

Technical Features

| Flow Rate | Up to 160 m³/h |

| Maximum Pressure | up to 48 Bar |

| Temperature range | -30° à +140 °C |

| Maximum Viscosity | 200.000 mPa s |